Correct tube seals done with Qseal-free withstand breakage at blood bag centrifugation

Linda Larsson, Julia Stojanovic & Hanna-Stina Ahlzén at Department of Clinical Immunology and Transfusion Medicine, Karolinska University Hospital. Linda Larsson also at Department of CLINTEC, Division of Transplantation Surgery, Karolinska Institutet.

Introduction

Tube seals that break during centrifugation is a common problem causing unnecessary loss of donated whole blood (WB). A study about tube seals and the impact of the mechanical stress of centrifugation, is therefore of great interest for blood component production. We have evaluated whether seals made on PVC tubes connected to blood bags represent a critical factor when the bags are exposed to high centrifugal force.

Questions

- How much centrifugation stress can seals at PVC tube ends withstand?

- Is the strength of the seal dependent on the content of the plasticizer DEHP in the tube?

Method

Starting material

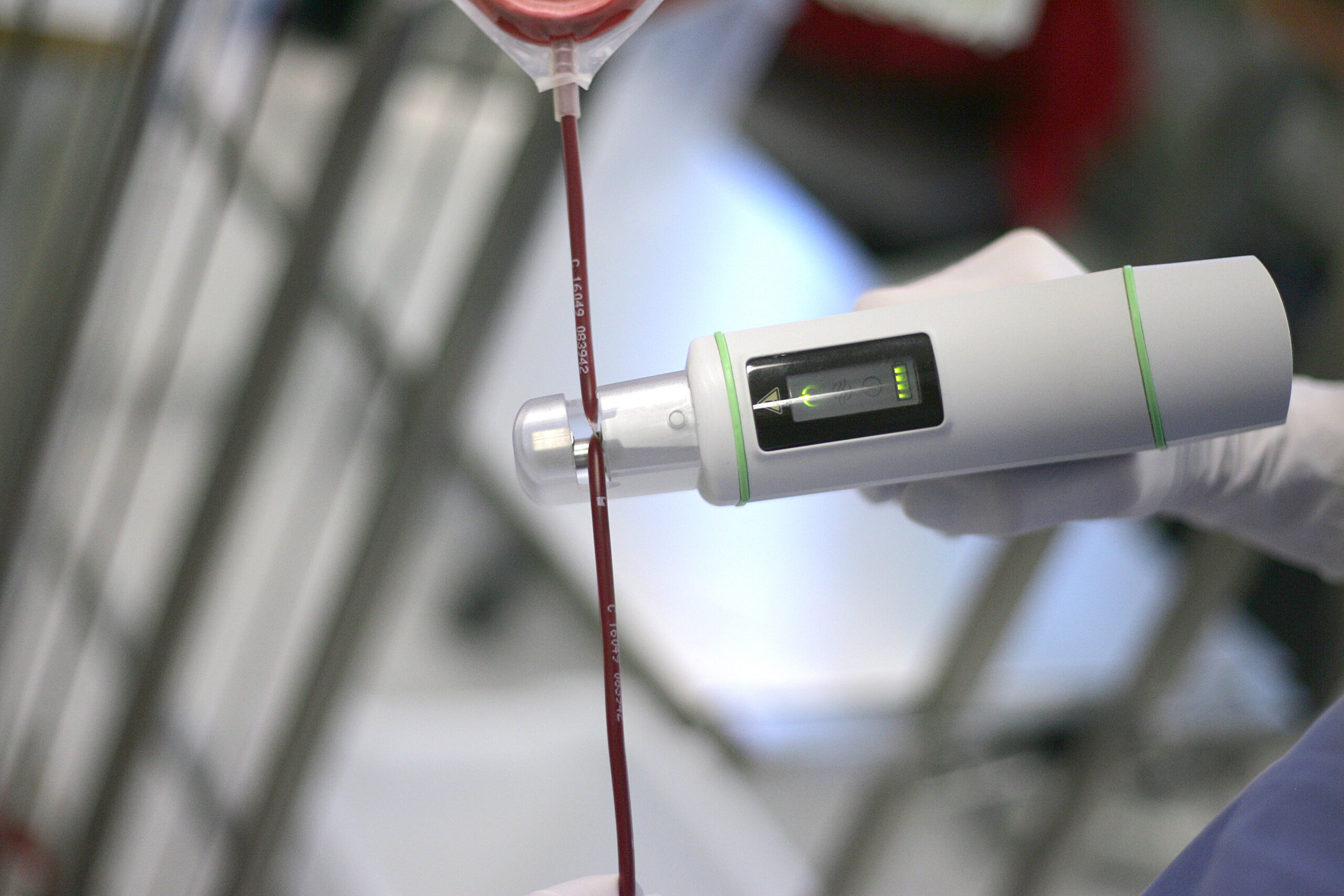

Single blood bags made of PVC containing either 35% DEHP (BB*T060CM, TerumoBCT, Lakewood, CO, USA) or 32% DEHP (MSV6000LU, Macopharma, Mouvaux, France) (N = 36 for each bag type) were filled 0.9% NaCl solution (AFAGE1324D, Baxter Medical AB, Kista, Sweden) ranging from 497-508 (median = 501) mL, representing a standard collection bag of 450 mL ± 10 % WB) + 63 mL CPD. Tubes were sealed with the cordless sealer Qseal-free (CS646, Conroy Medical AB, Upplands Väsby, Sweden) 12 cm from the bag while containing liquid.

Centrifugation

Seals were inspected and bags with flawless seals* were packed in centrifuge liners in a standardized way, with the bag label facing the middle of the centrifuge liner and the tube end facing downwards for maximum pressure on the sealed end. Padding was used to support and protect the bag and secure the position of the tube. Centrifugation was done in centrifuges (MacoSpin, Macopharma) at 4800 × g (rcf) for 11 min with maximum acceleration and semi-hard brake, representing an ordinary WB separation program with hardest possible g-force.

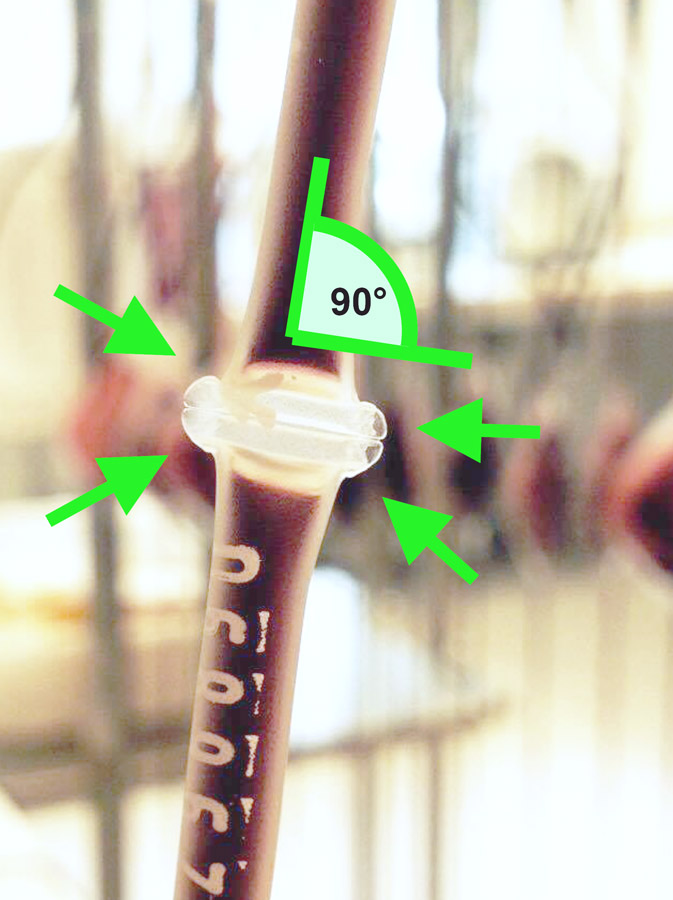

*definition of a flawless seal: placed at 90° angle in the centre of the tube and has melted plastic flaps protruding equally on both sides

Visual inspection

After every centrifugation cycle (CC), all seals were inspected. Any weaknesses in seals, broken seals or broken bags were registered. Unaffected units were re-centrifuged until broken or a maximum of 10 CCs.

Results

No leaks occurred at any of the sealed ends, regardless of DEHP content of the tube. However, leaks were observed in the filled bags, starting at the 8th CC. Therefore, not all seals were centrifuged 10 times.

Of the 35% DEHP units, 4 units displayed leakage after 8 CCs, 2 units after 9 rounds, and 4 units after 10 rounds. Of the 32% DEHP units, 2 units leaked after round 10. In total, 72 individual seals collectively withstood 701 CCs while remaining unaffected by the pressure of the centrifugal force.

Conclusion

Tube seals do not represent a weak point in blood bag centrifugation, provided that the sealing procedure is executed in a correct manner with an adequate tube sealer.

Qseal-free is a satisfying choice of tube sealer in terms of avoiding centrifugation seal breakage.

Summary

100% of the seals made with Qseal-free withstood all centrifuge cycles at maximum g-force without showing any signs of weakness or leakage. The repeated strain the seals were exposed to is well above what blood bags normally encounter, even though not all seals were exposed to 10 CCs. Hence, seal breakage at blood bag centrifugation is avoidable, regardless of DEHP content of the tube.

However, results of this study cannot be automatically transferred to other tube sealers of different models or brands; adequate stress tests should always be performed before new sealing equipment is taken into routine use. Whether problems with seals breaking in the centrifuge are a result of lower quality of the sealing equipment or poorly executed sealings, i.e. a need for better staff training, remains to be investigated.